![]() Current Issue

Current Issue

(Fall 2005)

Suspension of Disbelief

Amazing New Nanowires Could Help Missile Defense, More

Recent news about the possible development by other nations of nuclear and chemically armed ballistic missiles has put American missile defense back in the spotlight. And to keep America's missile defenses up to date, the U.S. Army is looking for help from nanotechnology researchers at U of L.

Nanotechnology refers to near-atomic-scale wires, tubes and other materials that have a wide range of potential applications in the military, medicine and in other fields.

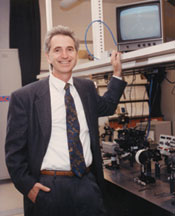

Electrical and computer engineering professor Robert Cohn is leading a team of six faculty members, several research scientists and students from Speed School and the physics department in the College of Arts and Sciences on a major research effort.

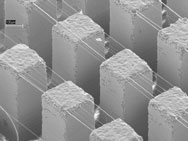

Speed professor Robert Cohn and a study team explore many ways to make near-atomic-sized nanotechnology devices. Cohn's team recently found a novel way to make bridge-like structures of 50-nanometer polymer wires suspended on pillars (pictured below).

So far, the “Nanowire Technology for Missile Defense” study has received federal funding totaling $3 million that supports research through September 2005, and Cohn expects additional installments as the team continues to develop pilot, or proof of principle, devices and materials.

“Missile systems are very complex, and the Army is looking for any technology that improves their missiles and systems to defend against the missiles of others,” Cohn says. “The question is: Can nanotechnology give us an edge?”

Nanowires could be used as electronics, sensors and mechanical actuators needed by warhead guidance systems to find their targets, Cohn adds. The research also could meet other military needs in sensing chemical threats or tracking hostile planes or missiles.

“In rockets or anything else that flies, you obviously want lighter-weight materials to improve fuel economy. Nanowire materials can provide this light weight together with a number of functions that can improve accuracy of guidance system,” Cohn explains.

“We're working on some nanoscale-sized sensors, for example,” he adds. “Sensors can detect all kinds of things—chemicals, light, colors, sound and more. A missile might need to recognize an object based on color, so we could possibly develop tiny sensors that can detect those colors or detect lasers set to certain wavelengths and so on.”

To boost the effort, Cohn's group is acquiring the best nanotechnology lab equipment available. The group recently received a grant from the National Science Foundation to buy a cutting-edge, virtual-presence surface-profiling microscope for nanomanipulation and nanoassembly.

The federal grant has provided for a high-resolution scanning electron microscrope and an advanced (Raman) spectroscopy instrument. Faculty team member Mahendra Sunkara also secured funds for an extreme resolution transmission electron microscope. The instruments together cost around $3 million.

Sen. Mitch McConnell has been instrumental in securing the funds both for the Army study and for the extreme resolution microscope.

“With equipment such as this, it's becoming very easy to manipulate objects and structures and to form or grow materials that are smaller than 100 nanometers, or one one-thousandth the diameter of a human hair and below,” Cohn says. “We're getting down to the size of atoms, which is on the order of two-tenths of a nanometer. And in that scale range it's becoming realistic to build materials from the bottom up and to make wonderful new devices.”

Cohn says there are many ways to make nanowires from raw materials by using lasers, electricity, force and heat to drive chemical reactions.

In one novel approach, Cohn has found a way to make structures that resemble tiny suspension bridges.

“We just reported a study in the journal Nano Letters in which we hand-brushed a liquid polymer over a surface of tiny pillars. The polymer dries, forming arrays of 50-nanometer wires suspended on the pillars.” Cohn says his team is investigating possible applications for such structures.

“Not long ago I wouldn't have thought it would be possible,” he says, “for someone to make a device by finding a wire you didn't even know was there, pushing it into position, making a measurement on it and doing it all in a little chamber while watching under a large microscope. And, in a few minutes, doing research that used to take a year to do.

“Now with the new tools available to us we have done entire research studies in an afternoon.”